Pultrusion

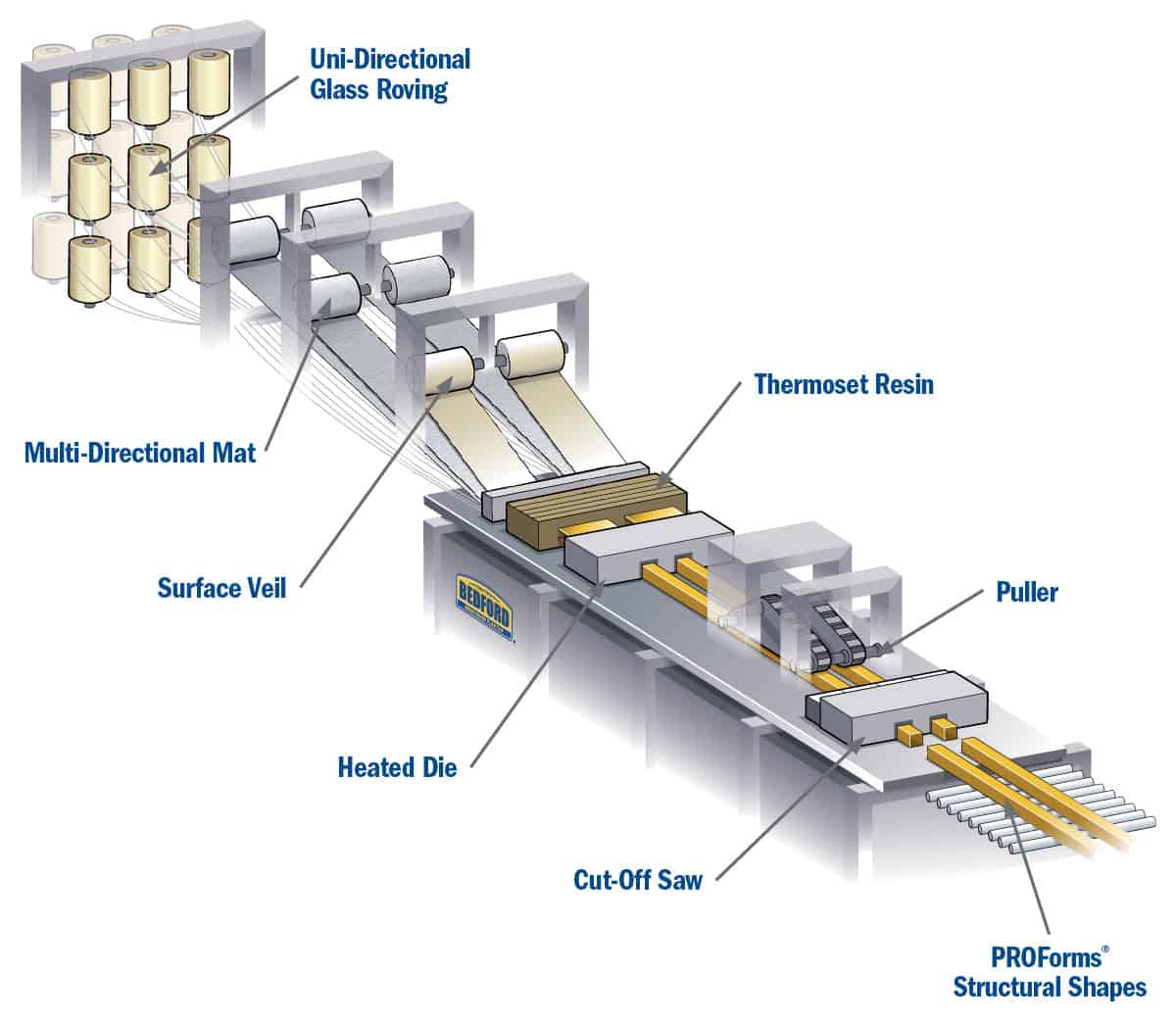

In the standard pultrusion process the reinforcement materials like fibers or woven or braided strands are impregnated with resin, possibly followed by a separate preforming system, and pulled through a heated stationary die where the resin undergoes polymerization. The impregnation is either done by pulling the reinforcement through a bath or by injecting the resin into an injection chamber which typically is connected to the die. Many resin types may be used in pultrusion including polyester, polyurethane, vinylester and epoxy. Resin provides the resistance to the environment, (i.e., the corrosion resistance, the UV resistance, the impact resistance, etc.) and the glass provides strength, in addition to safety from fire.

Products manufactured under this technology are widely used in the following industries:

Agriculture and Chemical

In the agriculture and chemical industries for manufacturing of chemically resistant to aggressive media slatted floors with enhanced strength characteristics used in the construction of livestock facilities, chemical plants and more

Construction

In the construction industry for the production of glass-fiber reinforcement, profiles, carcasses, stiffening bars for PVC-windows and more

Aerospace

In the aerospace industry for manufacturing of structure components of aircraft

Sports and Tourism

In the sports and tourism industries for manufacturing of equipment exhibiting enhanced strength properties: skis, ski poles, golf course flagsticks, tent and hovel constructions and move

Electrical Power Engineering

Commercial Production

In commercial production, using grains of long-fiber molding material (LLM) as a raw material for subsequent manufacturing of structures and products with enhanced strength and chemical properties

Automotive Industry

In the automotive industry for the production of structural and complex parts of the vehicles with enhanced stiffness, rigidity and lightness