Why FRP Liners?

Proper protection of your chemical tanks, sheds and other equipment in the corrosive chemical industry is necessary for the safety of your employees, your assets and the environment. Due to changing conditions in the chemical process, you not only need a trusted fiber glass liner, but also a partner who understands the complexity of these processes. Serving the chemical industry for over 30 years, we are here to share our experience and engineered solutions with you.

Our solutions are an individualized approach for each specific project. Because of different factors, we use innovation such as eliminating labor intensive acid brick linings in mixing tanks by introducing a dual-laminate system. Sometimes when the acid brick layer is inevitable, we can still work with you to get the job done. Our turn-key solutions include stripping the acid brick layer, stripping rubber, making steel repairs, blasting, applying new rubber lining and installing the acid brick layer. This way you have a single source for the entire project and only one contractor to get it done.

Kapilvastu Glassfiber offers FRP lining and coating of equipment such as field erected tanks, steel or concrete secondary containment pits, evaporators, absorbers, crystallizers, mixing tanks, storage tanks and many others. Often, the most chemical resistant linings are high corrosion and abrasion resistant epoxy vinyl ester resin and ISO resin. The type of protection always depends on the specifications of your project, characteristics of the acid and its corrosive nature. Our FRP linings provide protection against acids such as hydrochloric, sulfuric, nitric, phosphoric, hydrofluoric, chromic and sodium hypochlorite (bleach). In addition to internal tank linings, we offer protective coatings for the exterior of your vessels to fight against certain environmental conditions.

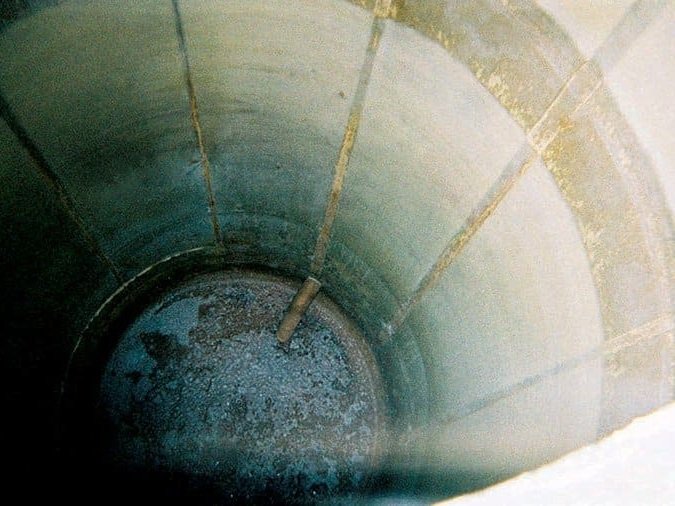

Most tanks need only one layer of FRP lining to be fully protected. However, in some cases, equipment such as tall field erected tanks will require a double lined floor to secure the bottom shell from fall velocity of the acid coming from the fill tube located at the roof of the tank. Double lining will absorb the impact of the falling acid and protect the bottom shelf.

If your existing lining fails, please contact us. We have emergency crews that will respond quickly to help solve your issues and make needed repairs. To avoid emergencies like this, we recommend regular inspections. Together, we can create an action plan to minimize possible costs of replacement and downtime.

We can design to your specifications and build at lower cost, as all the work will be completed in our shop or at your site as per the requirement. Kapilvastu Glass Fiber is a one-stop-shop for solutions and services for water treatment systems and pressure vessels in your chemical plant. For more information, please visit our website.